- W-97, MIDC, Anand Nagar, Ambernath (E), Dist: Thane, MH, INDIA, Pin: 421506

- sales@fluidtecq.com

In today's fast-paced industrial landscape, where precision, reliability, and efficiency are non-negotiable, businesses across sectors like food processing, chemicals, railways, water treatment, and oil & gas are constantly seeking innovative solutions to optimize their operations.

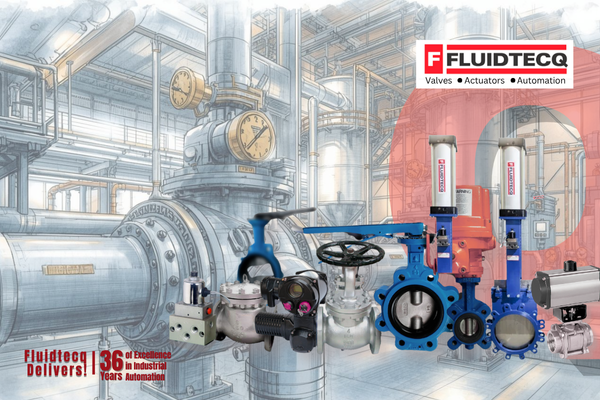

Enter Fluidtecq Pneumatics Pvt. Ltd.—a trailblazer in valve automation and solutions that's been engineering tailored pneumatic and industrial valve systems for over 36 years. With a technically sound team boasting a collective experience of more than 500 years among key management, Fluidtecq isn't just a supplier; it's a strategic partner committed to solving your unique challenges. Whether you're combating flow inconsistencies in a bustling food processing plant or ensuring seamless automation in high-stakes oil & gas environments, Fluidtecq's expertise ensures your systems run smoother, safer, and smarter. Let's dive into what makes Fluidtecq the go-to choice for valve automation solutions that deliver real results.

A Legacy of Innovation: 36 Years of Trusted Service and Diverse Expertise. Founded with a vision to redefine industrial pneumatics, Fluidtecq has served a diverse client portfolio spanning multinational corporations to niche OEMs. Our journey began over three decades ago, and today, we've evolved into a market leader in valves, solenoid valves, and automation solutions. This isn't just about longevity—it's about depth. Our key management team's combined 500+ years of hands-on experience translates into deep technical proficiency, from custom engineering to on-site troubleshooting. We've developed bespoke valve automation solutions tailored to specific industry requirements, ensuring compliance with global standards while addressing local pain points. In an era of geopolitical tensions and tariff wars, Fluidtecq proudly aligns with the Indian government's Make in India initiative. By prioritizing domestic manufacturing and innovation, we empower Indian industries to thrive independently, reducing reliance on imports and fostering self-sufficiency. This commitment not only supports national growth but also delivers cost-effective, high-quality products right to your doorstep.

Industries We Empower: Tailored Solutions for Key Verticals.

Fluidtecq's versatility shines through in the wide array of industries we serve. Our solutions are battle-tested in demanding environments, providing precision control that minimizes downtime and maximizes output. Drawing from our expertise, here's a focused look at how we support core sectors with specialized valves and automation:

Beyond these, our solutions extend to cement (rugged knife gate valves for abrasive materials), pharmaceuticals (sanitary-grade valves for clean-room precision), power generation (globe valves for high-temperature steam management), and more—adapting to diverse client needs from bulk material handling to pulp & paper.

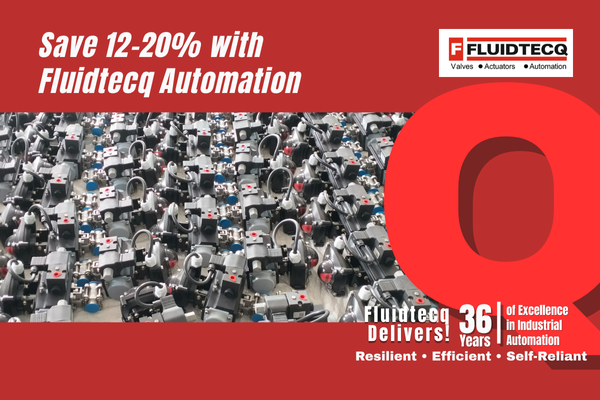

About Fluidtecq: Fluidtecq Pneumatics Pvt. Ltd. is a leading Indian manufacturer of industrial automation solutions, specializing in pneumatic valves, actuators, and related products such as Knife Gate Valves, Butterfly Valves, Ball Valves, Air Blaster Valves, and HVAC Dampers, designed for precise airflow control, energy efficiency, and durability in applications across industries including food processing, pharmaceuticals, dairy, oil & gas, chemical, power, cement, mining, wastewater treatment, pulp and paper, and water treatment. With a strong emphasis on the "Power of Q" – representing unwavering commitment to Quality, Quest for innovation, and Quick Solutions – Fluidtecq powers OEMs and plant builders with reliable, indigenous solutions under the #MakeInIndia initiative, enabling blockage clearance, efficiency boosts, and customized performance optimization. The company has recently slashed prices on its valves and actuators to support India's growing industries amid GST 2.0 reforms and global trade shifts, while providing essential maintenance techniques to extend product lifespan and avoid common mistakes for handling slurries, viscous fluids, and abrasive media