High-Purity Pharmaceutical Valves & Hygienic Flow Solutions

Fluidtecq Pneumatics Pvt. Ltd. is a premier manufacturer of high-precision pharmaceutical valves engineered for the rigorous demands of the biotechnology, API, and life-science industries. Our SS 316L hygienic valves are designed to ensure zero contamination, dead-leg free operation, and long-term reliability in sterile environments. Whether you require manual or actuated TC End valves , our products are fully compatible with CIP (Clean-in-Place) and SIP (Sterilize-in-Place) protocols.

Our Specialized Pharma Valve Range

1. Hygienic Pharma Butterfly Valves (H3) Our TC End (Tri-Clamp) Butterfly Valves offer seamless isolation for sterile lines.

- Design: Slim, space-saving hygienic design.

- Operation: Available in Manual Lever or Pneumatic Actuation.

- Finish: High-polish SS 316L (Ra ≤ 0.4 µm available).

Application: Ideal for clean utilities and sterile process lines.

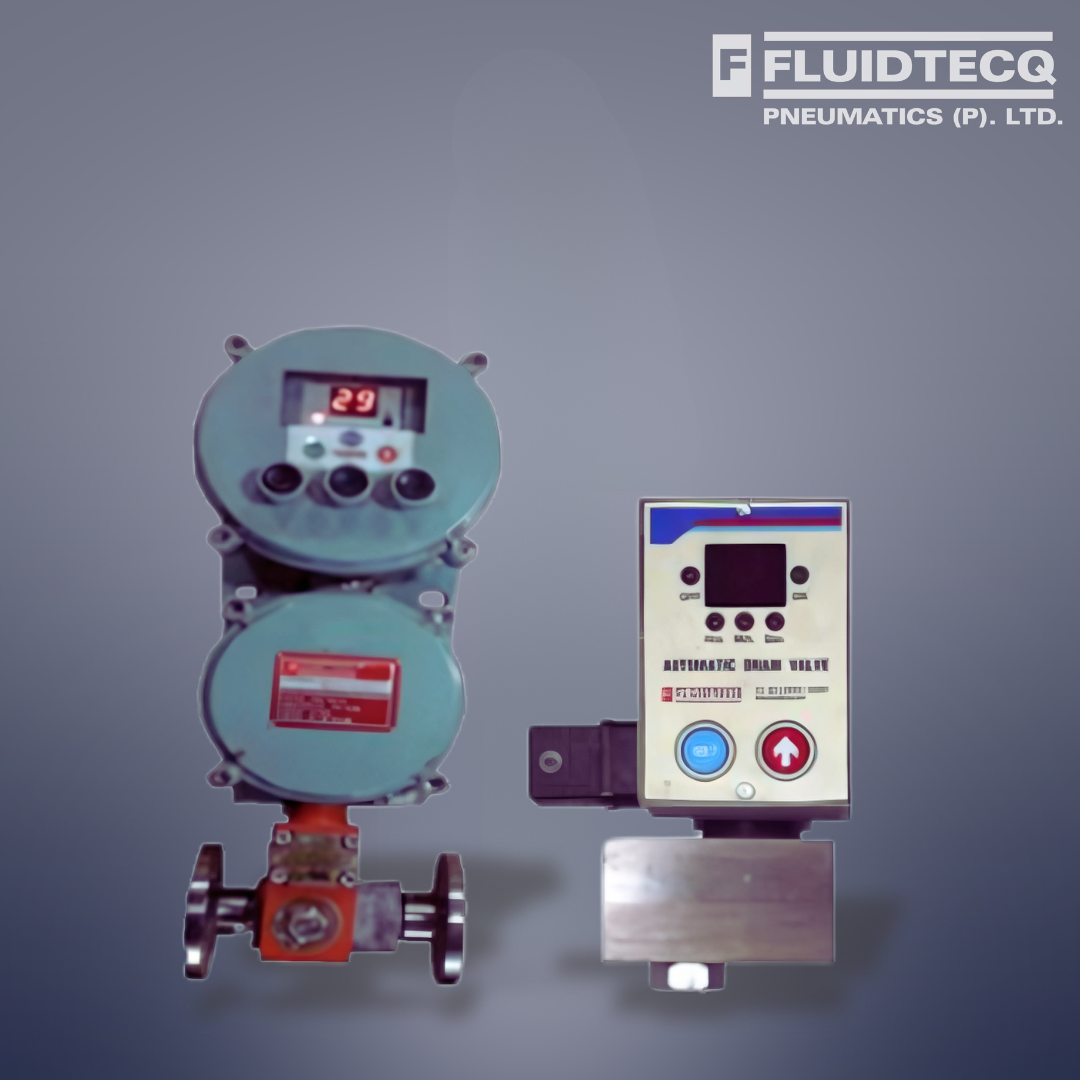

2. Precision Pharma Ball Valves

Designed for liquid, gas, and clean steam, our Pharma-grade Ball Valves provide a full-bore flow path to minimize pressure drop.

- Features: Cavity-filled seats available to prevent media entrapment.

- Connections: Tri-clamp, Flanged, or BSP.

- Sealing: FDA-approved PTFE/EPDM seals for leak-proof performance.

3. Sanitary Auto Drain Valves Eliminate condensate buildup in your clean steam systems. Our Pharma-grade Auto Drain Valves prevent product hold-up and maintain system sterility.

- Benefit: Zero hold-up design for hygienic piping.

- Durability: Built for high-temperature steam applications.

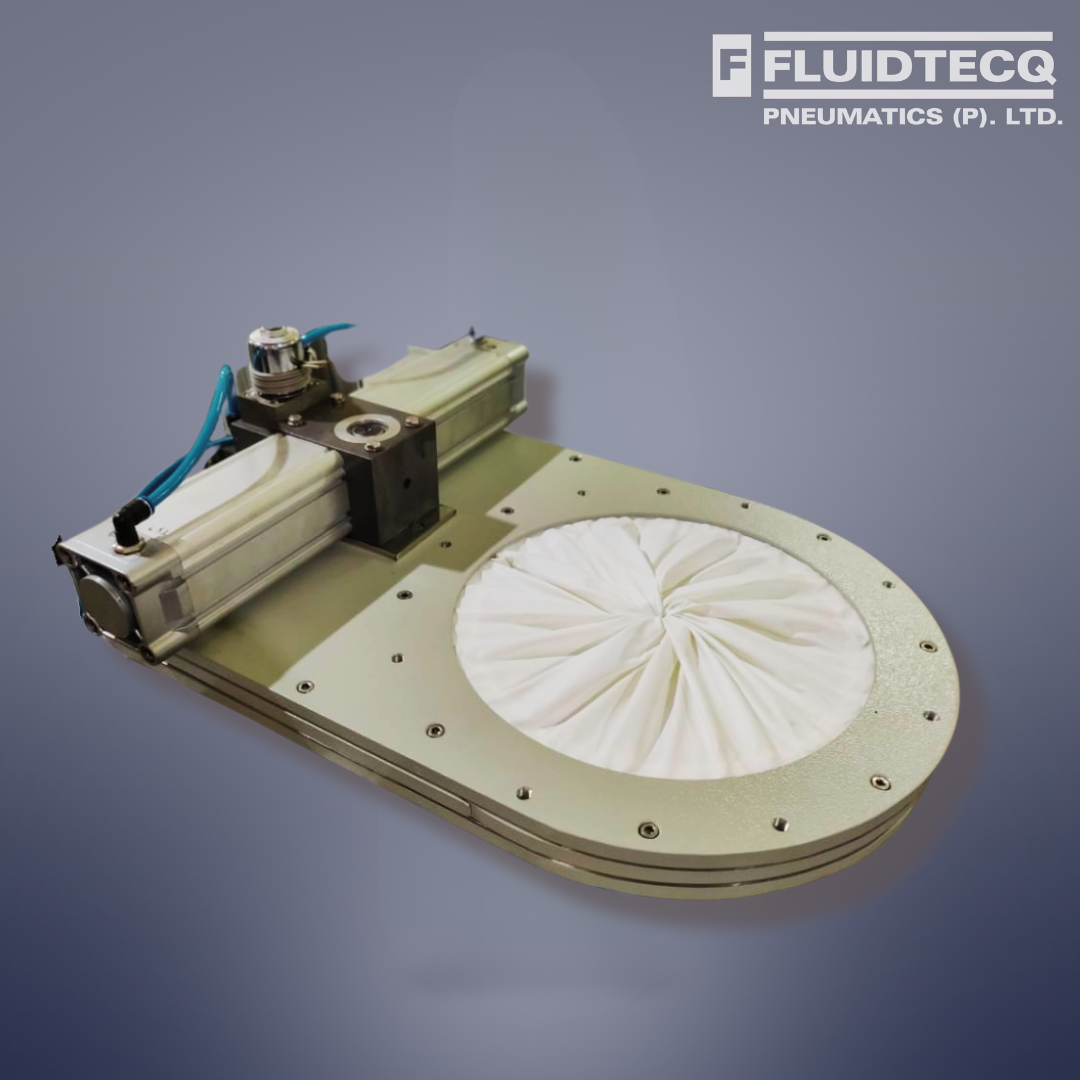

4. Iris Valves for Powder Handling

For gentle control of powders, granules, and slurries, our Hygienic Iris Valves ensure no contact between the process media and mechanical moving parts.

Technical Excellence & Compliance

- Materials: Certified SS 316 / SS 316L (Low Carbon).

- Compliance: FDA-approved seats and USP Class VI compliant elastomers.

- Surface Finish: Standard Ra ≤ 0.8 µm; Electropolishing to Ra ≤ 0.4 µm for critical biotech applications.

- Dead-Leg Free: Engineering focus on "Zero Hold-Up" geometry.

Key Applications

- WFI & Purified Water Systems: Maintaining water conductivity and sterility.

- API Manufacturing: Handling aggressive chemicals with high-purity standards.

- Fermentation: Precise flow control for bioreactors.

- Clean Steam Lines: Robust valves for SIP cycles.

Why Partner with Fluidtecq?

As an ISO and ZED certified manufacturer , Fluidtecq provides more than just hardware.

We offer:

- Customization: Valves tailored to specific ASME BPE standards.

- Traceability: Full MTC (Material Test Certificates) 3.1 provided.

- Global Quality: Competitive pricing for world-class, leak-tested pneumatic solutions.