Fluidtecq Bonneted Knife Gate Valves

Zero-Leak Isolation & Total Fugitive Emission Control

In critical process environments—where toxic gases, hazardous chemicals, or high-pressure slurries are the norm—standard valves are a liability. Fluidtecq’s Bonneted Knife Gate Valves are engineered to provide a 100% pressure-tight seal, ensuring that your media stays exactly where it belongs: inside the pipe.

The Bonneted Advantage

While standard open-yoke valves expose the gate to the atmosphere, our Bonneted Design features a fully enclosed, pressure-tight housing.

Zero Fugitive Emissions: The primary choice for the Chemical and Pharmaceutical sectors to prevent the escape of hazardous vapors or costly media.

Vacuum Integrity: Ideal for pneumatic conveying systems where maintaining a perfect vacuum is critical to process efficiency.

Contaminant Shield: The bonnet protects the stem and internal gate from external dust, grit, and corrosion, making it perfect for Ash Handling and Mining .

High-Pressure Reliability: Engineered to withstand pressure surges and prevent packing blowouts, exceeding standard MSS SP 81 benchmarks.

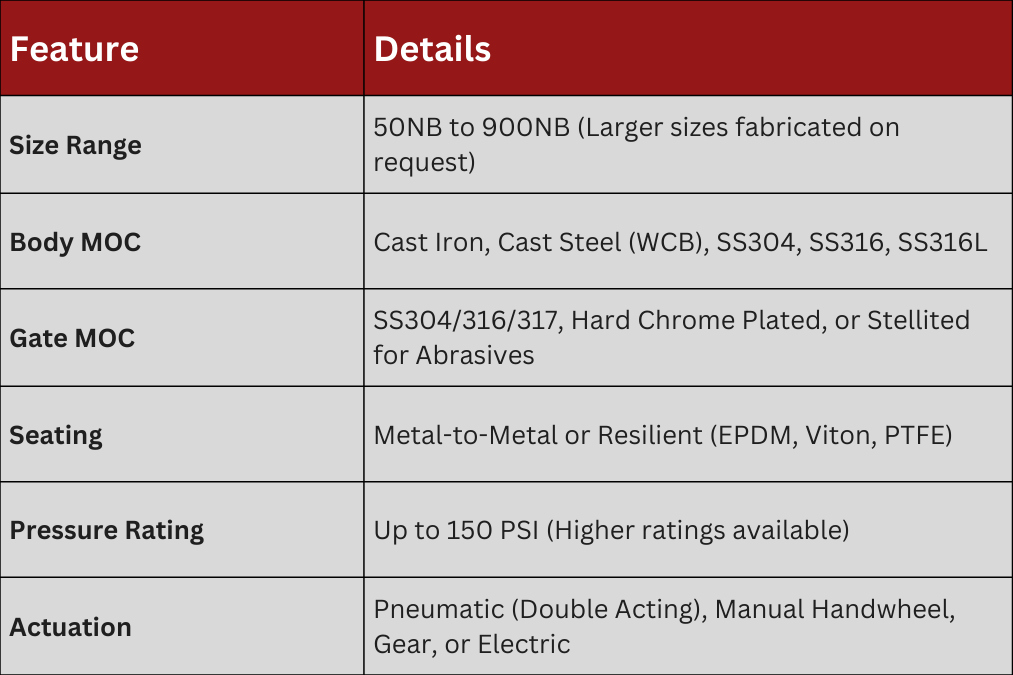

Technical Specifications

Why 70% of India’s Top OEMs Rely on Fluidtecq

Fluidtecq is more than a manufacturer; we are an automation partner. Our dominance in the Indian market is built on verified performance:

PESO Certified: Flameproof solutions for hazardous and explosive zones.

ZED Bronze Certified: Complying with "Zero Defect, Zero Effect" manufacturing.

ISO 9001:2015: 35+ years of quality management and engineering excellence.

CIMFR Approved: Rigorously tested for safety in mining and power research.

"Quality with Responsibility"

"Fluidtecq... Quality with Responsibility." — Hemal Mehta, Director

Every Fluidtecq valve is designed only after our engineers collect and analyze your specific application data—slurry density, chemical pH, and temperature—to ensure 100% operational reliability.

Target Industries

Power & Steel: Fly ash, bed ash, and abrasive slurry handling.

Chemical & Pharma: Volatile organic compounds and toxic fluid isolation.

Food & Dairy: Hygienic powder conveying and viscous liquid control.

Wastewater: Methane-rich sludge and abrasive grit isolation.

Request a Quote & Technical Consultation

Upgrade your plant safety with the brand trusted by India's engineering giants.

https://fluidtecq.com/contact

https://fluidtecq.com/contact