Surface Finish: Ra ≤ 0.4 µm for True Cleanability

Even the best stainless steel grade cannot guarantee sterility if the surface is rough or porous. Fluidtecq offers high-grade electropolishing with options for surface roughness up to Ra ≤ 0.4 µm on wetted surfaces to eliminate microscopic crevices where biofilm and bacteria can anchor. This ultra-smooth finish improves cleanability, reduces cleaning cycle times, and supports compliance with global pharmaceutical hygiene guidelines.

Traceability and Documentation: MTC 3.1

Every valve is supplied with Material Test Certificates (MTC 3.1), ensuring full heat-number traceability for all pressure-retaining components. This documentation supports regulatory audits and quality systems such as cGMP, making it easier for QA and validation teams to qualify Fluidtecq valves for critical pharma and biotech installations.

Critical Valve Types for Modern Pharma Plants

Modern pharma and biotech facilities demand valves that can handle sterile liquids, clean steam, and sensitive powders with equal reliability. Fluidtecq offers a focused range of valve solutions engineered for these environments.

1. Hygienic Butterfly Valves (TC End)

Hygienic butterfly valves are widely used for line isolation and transfer in purified water, WFI, and process media lines. Fluidtecq’s hygienic butterfly valves feature Tri-Clamp (TC) ends for fast installation, easy maintenance, and minimal dead space in piping runs.

Key advantages:

- CIP/SIP compatibility: The design is fully suitable for Clean-in-Place (CIP) and Sterilize-in-Place (SIP) processes, allowing repeatable sterilization without dismantling.

- Hygienic sealing: Valves are available with FDA-approved EPDM, Silicone, or PTFE seats to match media, temperature, and chemical compatibility requirements.

- Compact and lightweight: Ideal for skid-mounted systems and tight utility corridors in pharma plants.

2. Dead-Leg Free Ball Valves

Standard ball valves often create cavities where product or condensate can accumulate, posing a contamination and validation risk. Dead-leg free or cavity-filled designs eliminate these pockets and are essential in high-purity liquid and steam applications.

Fluidtecq pharma-grade ball valves incorporate cavity-filled seats that prevent product hold-up within the valve body. Benefits include:

- Reduced risk of contamination in WFI loops, clean steam lines, and critical process manifolds.

- Improved drainability and flushing during CIP/SIP, supporting robust cleaning validation.

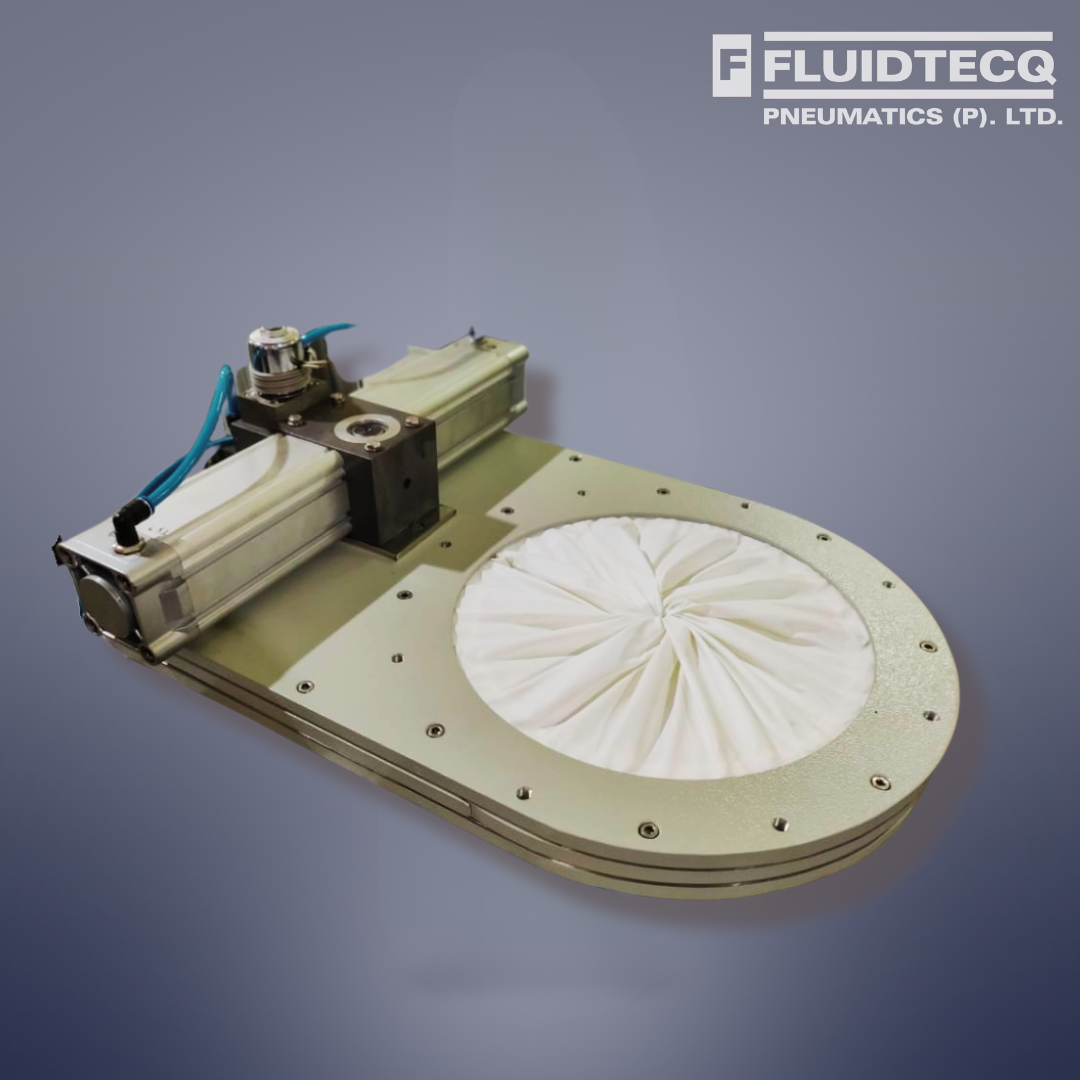

3. Precision Iris Valves for Powder Handling

Delicate powders, granules, and active pharmaceutical ingredients (APIs) require gentle handling to avoid particle degradation, segregation, or dust generation. Traditional slide gate or butterfly designs can pinch or shear product, affecting yield and quality.

Fluidtecq Iris Valves offer a flexible, diaphragm-like opening that closes uniformly around the product stream. This delivers:

- Gentle handling: No direct contact between moving metallic parts and process media, making the valve ideal for sensitive powders, capsules, and granules.

- Infinite control: Stepless throttling enables precise dosing and flow control in reactor charging systems, bin discharging, and tablet/capsule handling lines.

Designed for Compliance and Automation

Pharmaceutical plants increasingly rely on automated, data-driven control systems to maintain quality and throughput. Fluidtecq valves are designed to integrate seamlessly into modern automation architectures.

- Automation-ready: Valves can be supplied with high-precision pneumatic actuators, solenoid valves, and limit switch boxes for reliable on/off or control duty in PLC/SCADA-based systems.

- Elastomer compliance: All elastomeric components are available in FDA and USP Class VI compliant grades, supporting global regulatory expectations for contact materials in pharma and biotech service.

This combination of hygienic design, material compliance, and automation readiness makes Fluidtecq valves suitable across a broad range of applications including WFI distribution, clean utility panels, bioreactors, filtration skids, and sterile filling lines.jornen+1

Application Snapshot: Where Fluidtecq Valves Fit

Fluidtecq’s high-purity valves are engineered to support critical pharma and biotech processes such as:

- WFI and purified water loops where zero dead-leg and high surface finish are essential for controlling microbial growth.

- Clean steam distribution for sterilization of reactors, fermenters, and filling equipment.

- Reactor charging and discharge of APIs, excipients, and granules using Iris Valves for accurate and gentle flow control.

By combining SS 316L construction, Ra ≤ 0.4 µm electropolished finishes, cavity-free internal geometries, and validated elastomer options, Fluidtecq provides a robust, audit-ready foundation for hygienic valve selection.

Protecting Product Purity with the Right Valve Partner

Choosing the right valve is not just a mechanical decision—it is a quality and compliance decision that directly impacts product safety, batch integrity, and regulatory outcomes. From WFI systems and clean utilities to reactor charging and sterile packaging lines, Fluidtecq Pneumatics Pvt. Ltd. delivers engineered valve solutions that help safeguard product purity in high-stakes life science applications.

To discuss your specific pharma or biotech project, you can align SS 316L, CIP/SIP compatible, Ra ≤ 0.4 µm valve solutions from Fluidtecq with your URS, validation, and audit requirements.